Dyson vacuums are sophisticated appliances, and when they malfunction, professional repair is often necessary. Many users searching for “dyson 維修” wonder about the repair process. Understanding a step-by-step guide—from diagnosis to solution—helps you appreciate how skilled technicians restore your vacuum to peak performance.

Step 1: Initial Inspection and Diagnosis

The repair process begins with a comprehensive inspection. Technicians check for common issues like loss of suction, brush bar problems, battery faults, and motor irregularities. Accurate diagnosis ensures that the root cause is identified, preventing unnecessary repairs and reducing downtime. Professional dyson 維修 focuses on precision to ensure efficient solutions.

Step 2: Identifying Faulty Components

After inspection, faulty components are identified. This could include brushes, batteries, filters, wiring, or motors. Each part is assessed for damage or wear. Proper identification is essential to ensure that the repair addresses the true problem, avoiding repeat issues and additional costs.

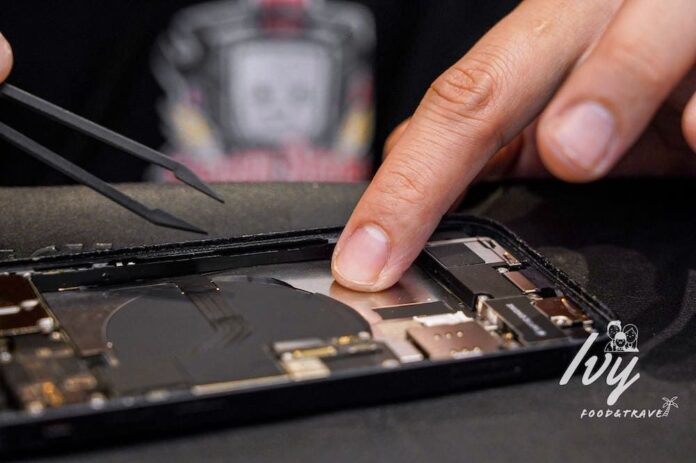

Step 3: Disassembly and Component Removal

Once defective parts are identified, technicians carefully disassemble the vacuum. Proper handling prevents further damage to sensitive components. Skilled dyson 維修 technicians follow manufacturer protocols to ensure safe removal and replacement of parts.

Step 4: Component Replacement or Repair

Defective components are either repaired or replaced with certified parts. Motors, brush bars, batteries, and filters are restored to full functionality. Using high-quality parts guarantees that the Dyson vacuum continues to operate efficiently after dyson 維修.

Step 5: Reassembly and System Checks

After replacement, the vacuum is reassembled with precision. Technicians ensure that all components are correctly aligned and securely installed. This step is critical to prevent future malfunctions and maintain performance.

Step 6: Performance Testing

Comprehensive testing ensures that the vacuum functions as intended. Suction, brush bar rotation, battery performance, and electrical safety are all evaluated. Successful testing confirms that dyson 維修 has fully resolved the issue, restoring peak performance.

Step 7: Post-Repair Recommendations

Technicians provide advice on preventive care to reduce future problems. This may include filter cleaning schedules, brush bar maintenance, and battery care tips. Educating users complements dyson 維修, extending the vacuum’s lifespan.

Step 8: Warranty and Support

Professional dyson 維修 often includes warranty coverage for repaired or replaced components. This protects customers from recurring issues and ensures that any new problems are addressed promptly, providing peace of mind and long-term reliability.

Step 9: Environmentally Responsible Practices

Repairing rather than replacing a Dyson reduces electronic waste. Recycled parts and durable replacements contribute to sustainability while ensuring high-quality performance.

Final Thoughts

A step-by-step dyson 維修 process—from diagnosis to testing—ensures efficient, reliable, and long-lasting repairs. Skilled technicians, certified parts, and thorough testing restore vacuums to optimal performance, providing users with peace of mind and value for money.